The Hidden Costs of Staying Manual

August 13, 2025

Why the status quo is costing your pharmacy more than you think

For many pharmacy leaders, manual workflows feel “good enough” — orders are getting out the door, and customers are being served. But there’s a cost to maintaining that status quo, and it’s not always visible on a spreadsheet.

When you add up the lost time, increased labor costs, and hidden operational inefficiencies, staying manual can quietly drain your margins. Here’s what you may not be seeing.

1. Overtime and Extra Shifts

When your team regularly stays late to clear the queue, those hours add up quickly. Beyond the direct wage cost, overtime increases fatigue and turnover, which can cause further disruptions — and even more overtime to cover the gaps.

2. Higher Error Rates

Manual packing and labeling naturally leave more room for human error. Even with the best staff, repetitive tasks lead to mistakes. Every error costs time (for rework) and money (for replacement meds) — not to mention the risk to patient safety and your reputation.

3. Slower Turnaround Times

Manual processes can’t run at full capacity outside staffed hours. That means morning shifts start with a backlog, and urgent requests create bottlenecks. Over time, slower fulfillment can impact customer satisfaction and facility relationships.

4. Lost Opportunities

Time spent on repetitive packing is time not spent on higher-value tasks — like inventory optimization, staff training, or clinical interventions. These missed opportunities have a real but harder-to-measure cost in long-term efficiency and customer trust.

5. Scaling Pain

When your volume grows, manual workflows require more people, more hours, and more space to keep up. That means growth comes with a proportional increase in overhead — and a greater risk of burnout for your team.

The Annualized Impact

One extra hour of overtime per day for five techs is over 1,200 hours a year — the equivalent of adding another full-time salary without increasing output. Combine that with the cost of rework, turnover, and delayed deliveries, and the “hidden” costs start looking a lot like major budget items.

The Case for Acting Early

Every month you delay exploring automation, you’re leaving efficiency — and profitability — on the table. Planning ahead means you can integrate automation before you hit breaking points in volume or staffing.

Next Step: Find Out Your True Costs

Our Free Workflow Review doesn’t just identify where automation fits — it reveals where you’re losing time and money today. The results may surprise you.

Get started

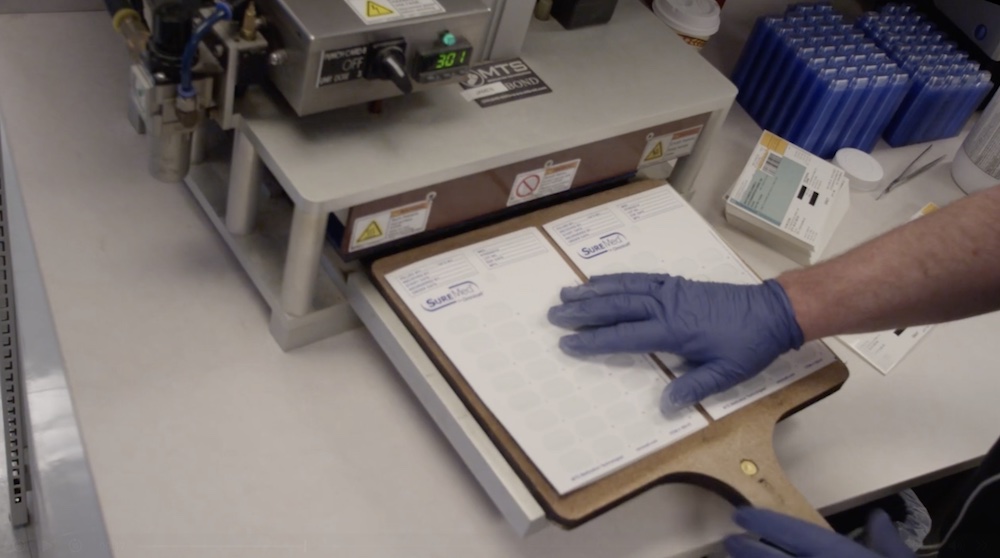

We’d love to give you a Demo

Seeing is believing with the DOSIS System. See for yourself the value of DOSIS workflow through a full demo of a working system.

Schedule a Demo